Just

in time for summer, we completed our annual BOOT CAMP and the results are in!

We have become physically stronger, and we are ready to enjoy the summer fun!

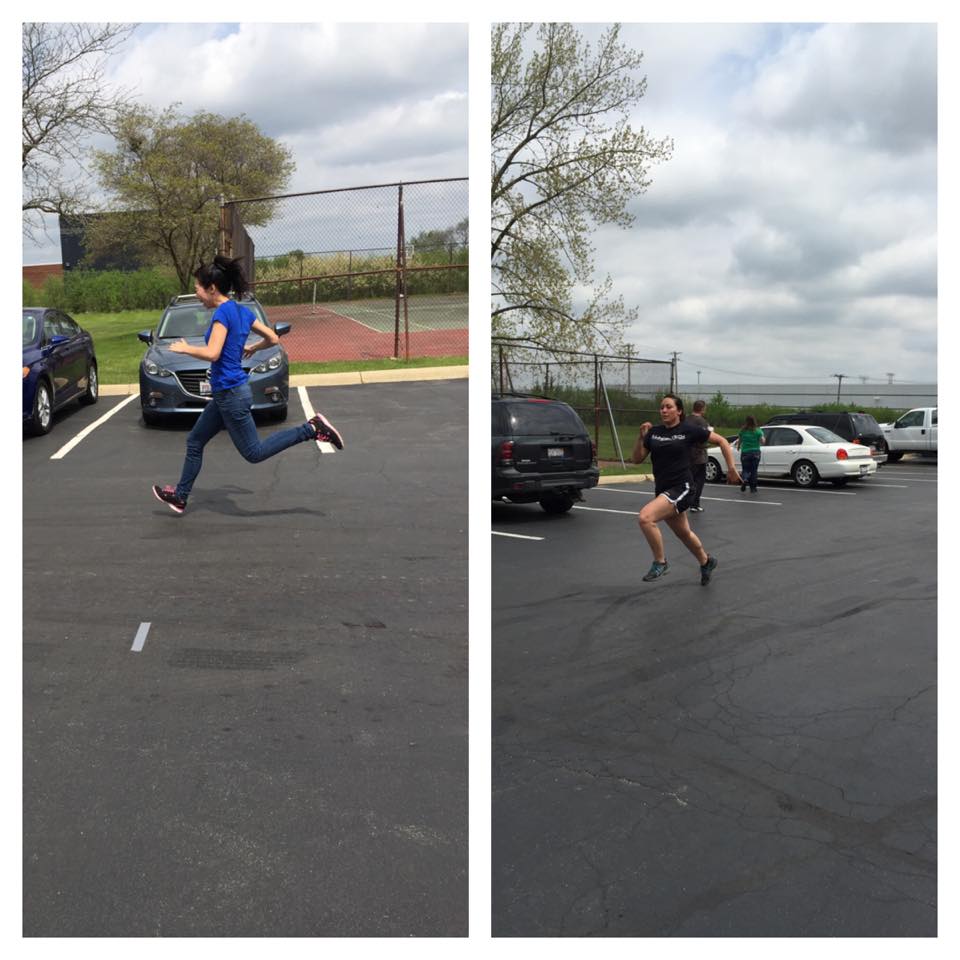

BOOT CAMP started on May 4th with initial tests in planks, sit-ups,

squats, push-ups, vertical jumps and a 40 yard dash. Employees had 6 weeks to

improve their scores from the initial results.

Overall,

12 participants improved their scores by at least 20%. The average improvement

was 33%. Our top 2 winners went well above the average:

Most Improved

Performer: Irma

Carrera, QA Inspector II—improved her score by 131%

Most Improved

Runner-Up:

Pravina Panchigar, QA Inspector IV—improved her score by 86%

OSG

also has some great performers who demonstrated their physical strength with

the highest test scores!

Highest Performing

Female: Alyssa

Walther, Applications Engineer

Highest Performing

Male: Ian

Duncan, Inventory Control Planner

You are probably wondering how well they performed in the

tests. Our highest performing female, Alyssa, who practices volleyball

regularly, excelled in the squats and vertical jump tests and the 40 yard dash.

Her vertical jump score was 19.50 inches, and she ran the 40 yards in 5.50

seconds! Our highest performing male, Ian, also showed his strength in the

plank test. He held a plank for over 2 minutes! According to the research,

average men should be able to hold a plank for at least a minute, so Ian went

well above the average.

Summer just started, and it is not too late to kick-start

your fitness. From OSG BOOT CAMP, we recommend the plank to improve your core

stability and strength. It is likely that you have great physical fitness if

your core is strong. Not only does the plank exercise strengthen your body, but

it also improves your mood! If you sit at your desk all day at work, your

muscles tighten up. According to LIVE STRONG.COM, we are able to stretch stiff

muscles that contribute to stress by practicing the plank exercise. In

addition, plank exercise can help calm your brain to reduce stress!

Congratulations to the winners and stay tuned for the OSG’s

next fitness challenge!

Contact Us

Contact Us  Product Search

Product Search