“Dirty floors and oily machines?” “That’s my grandpa’s age,” said Yuchieh Lou, a student from Harper College. Manufacturing students from Harper College in Palatine, Illinois received first-hand exposure to today’s manufacturing as a high tech field and hopefully, are considering manufacturing as a viable career option. On Wednesday, April 6th, 14 students who are enrolled in the Manufacturing Technology Program at Harper College visited OSG’s carbide tooling factory in Bensenville for a field trip. This was conducted as part of OSG’s ongoing Manufacturing Day programs to inspire and support the next generation of manufacturing personnel.

Students started the day hearing presentations about OSG and available career paths. Our HR Generalist, Paul Wilhelm, explained to the students that the retirement of baby boomers is opening up positions for the younger generations in manufacturing. However, it is also creating a skills gap between the skills manufacturers are losing but require and the skills younger people have. Today’s manufacturers require new personnel to have more expertise in manufacturing such as STEM (science, technology, engineering and mathematic) skills at an earlier stage of their career to close this gap.

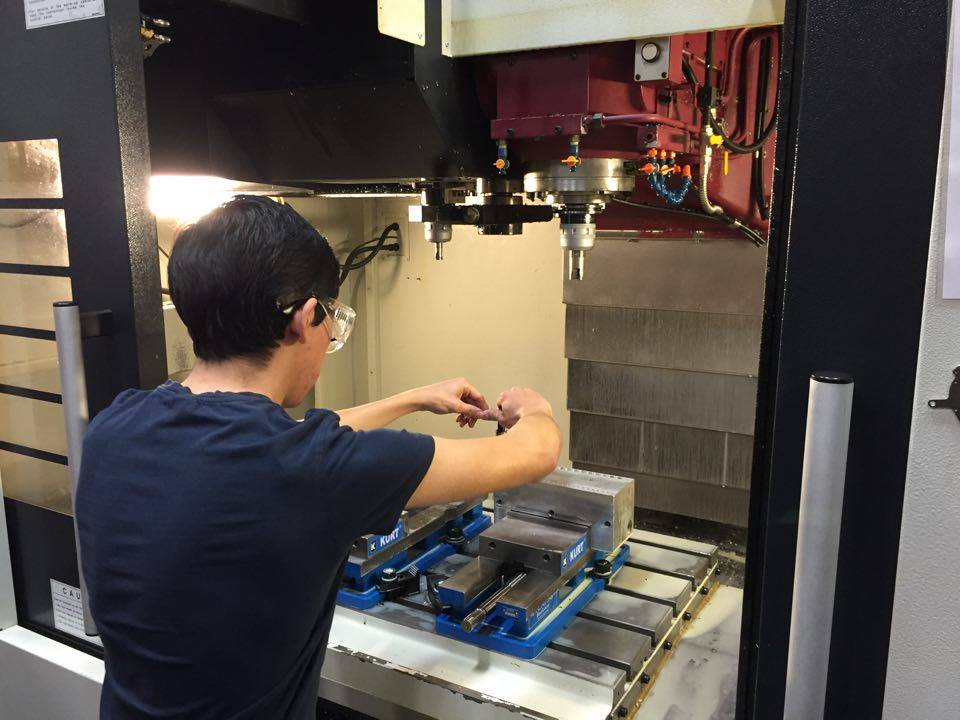

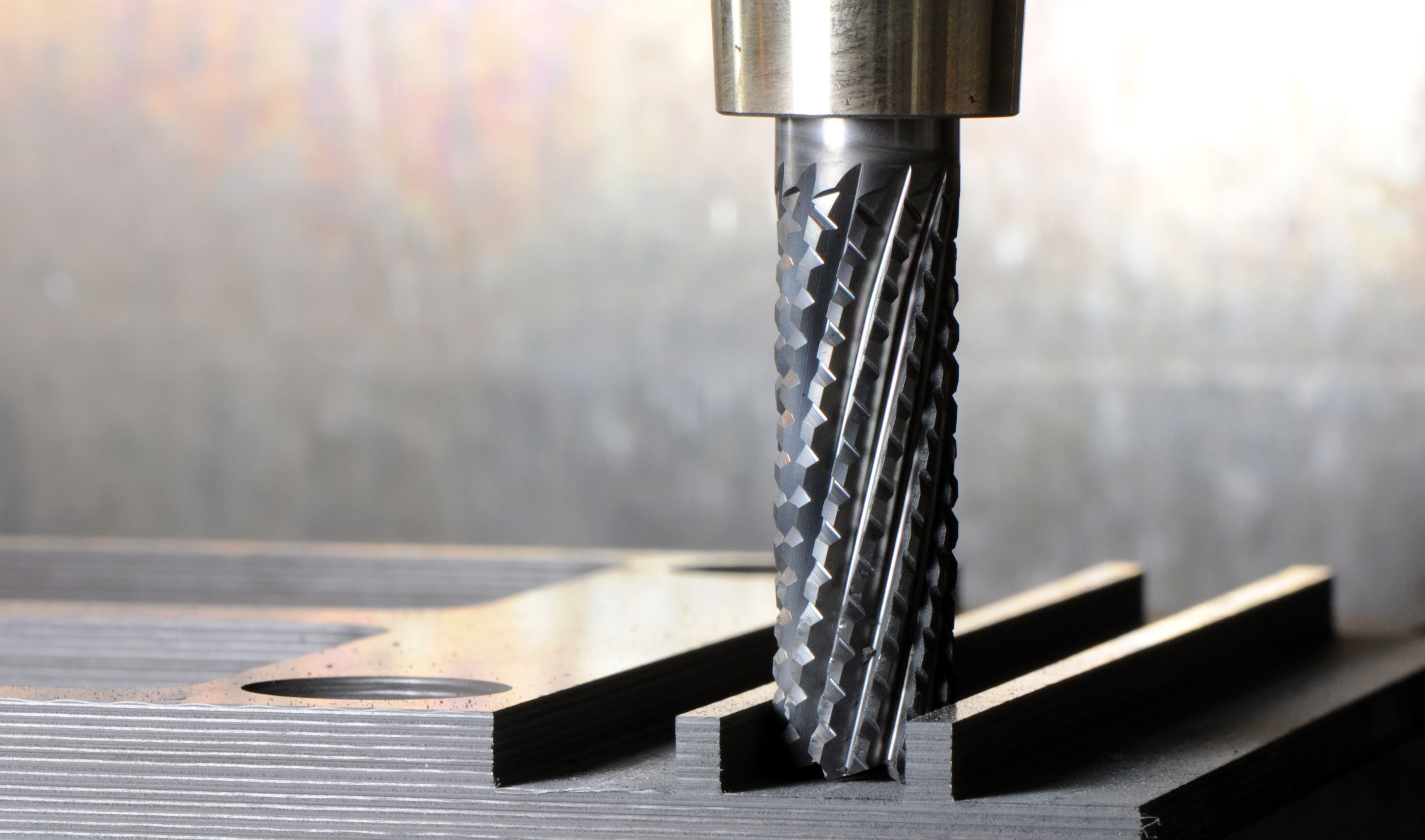

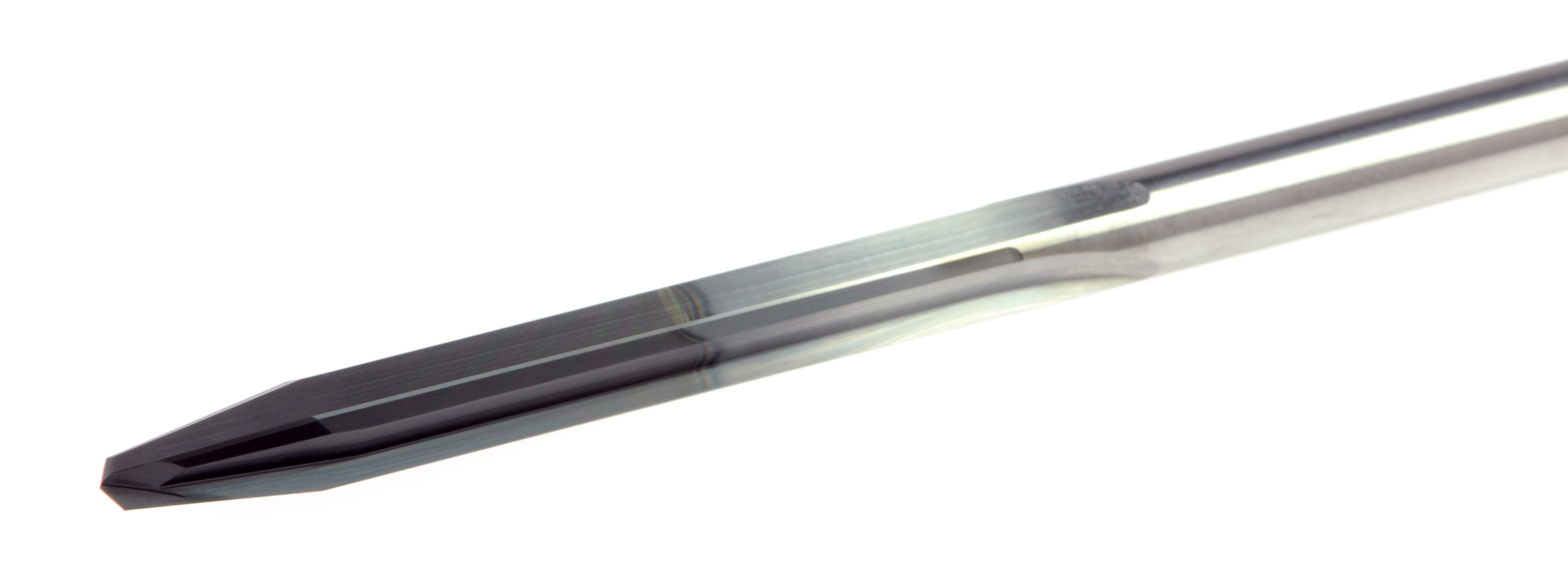

The students also learned about OSG products through tooling demonstrations in our R&D center. Lukasz Gaca, Machining Applications Engineer at OSG, showed various OSG tools in action. Students also tried hand tapping in a block of aluminum to provide them with some hands on experience with tapping tools.

“One of the exciting things about manufacturing is to create something from raw material,” said Dan Jack Combs, a Harper College student.

After the tooling demonstrations, the students were taken on a plant tour. They were able to see OSG’s manufacturing floor in action with more than 60 CNC machines and in-house coating vessels for patented OSG CVD Diamond and AlTiN/TiAlN coating.

“From this visit, I realized that modern manufacturing does require higher technical skills,” said Billy Tsiveriotis, a Harper College student.

Harper College’s manufacturing department focuses on career readiness using a combination of classroom theory and hands on training with state-of-the-art machines that students will likely to encounter in the industry.

“Our goal in the manufacturing program at Harper College is to improve the caliber of students coming out of the program and getting hired by manufactures,” said Aaron Kolb, an instructor of the Manufacturing Technology Program at Harper College. “Manufacturing has become a high-tech career path with many options, and we work hard to make sure our curriculum matches the needs of manufacturers.”

OSG’s production team is hopeful and excited about the future of manufacturing as they interacted with the student and experienced their motivation and interest in manufacturing.

“Some of the students asked me what constitutes the best employees,” said Chuck Abate, Plant Manager of the OSG Bensenville factory. “I stressed teamwork, integrity and ability to continually learn in addition to technical skills.”

In order to help students get additional experiences and prepare for their manufacturing career, OSG offers an internship program at the Bensenville factory.

Courtesy of Composites Manufacturing

Courtesy of Composites Manufacturing

Contact Us

Contact Us  Product Search

Product Search