08

February 2016

Are you having issues with peel-up, thrust and delamination when drilling or reaming carbon and glass fiber composites? These composites are constructed with layers of material that are prone to delamination. You are probably having problems with your tool life as well. Carbon fiber is known to be abrasive, and could easily wear your tool down. If your tool loses its sharpness, it pushes the material away instead of cutting, producing uncut fibers. This forces you to continually monitor your tools while machining.

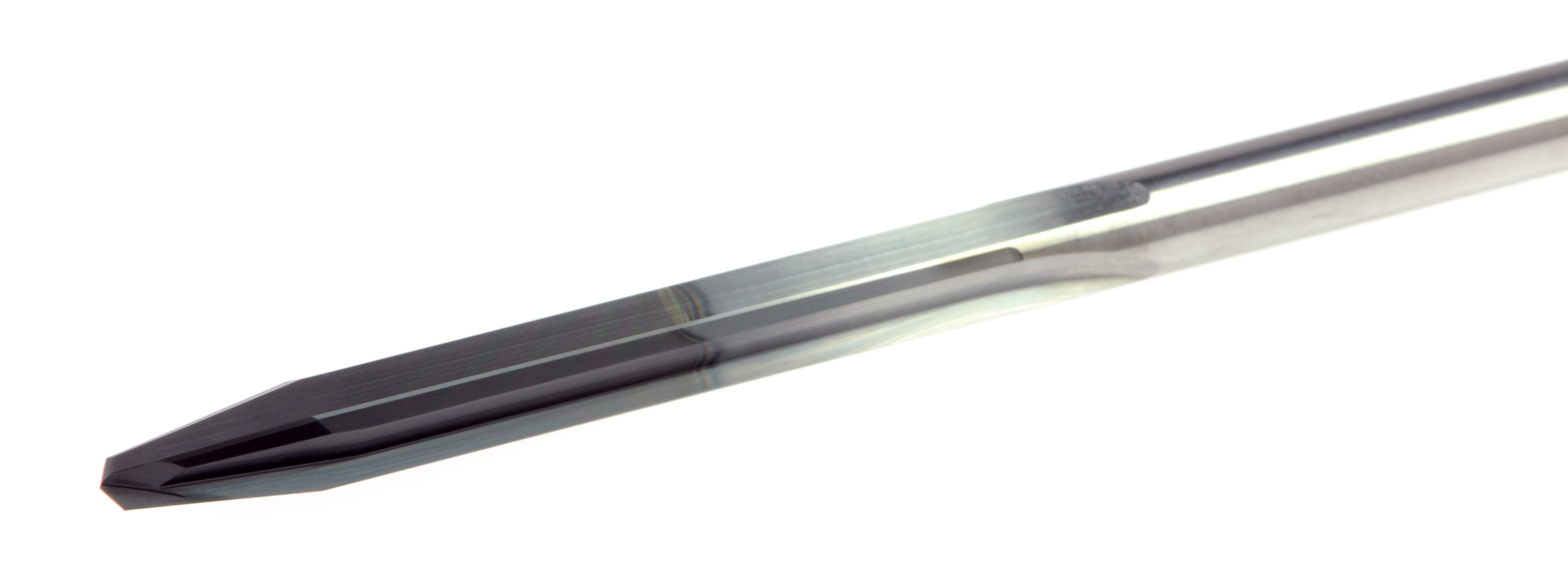

With OSG’s EXOPRO® AERO-D-REAM, you can machine carbon and glass fiber composites without worrying about tool life. The AERO-D-REAM features OSG’s patented diamond coating which significantly improves tool life and hole quality. The coating has a maximum diamond grain size diameter of 2µm. This strictly controlled diameter allows our coating to be super smooth and extremely sharp! We also utilize grinding techniques on our special carbide substrate which prolongs tool life.

When the AERO-D-REAM was compared to its uncoated counterpart, it was able to drill 14 times more holes and provided better hole quality. At 180 holes, it did not show any signs of margin wear!

In addition, the AERO-D-REAM has a tapered-4-flute design to limit peel-up at hole entrance as well as elongated double-angle geometry to reduce thrust and limit exit delamination.

Sounds too good to be true? We are currently offering promotional deals to save up to 15% on our aerospace tools including the EXOPRO® AERO-D-REAM! Click here to learn more about our deals.

Contact Us

Contact Us  Product Search

Product Search