Paul Garcia, a sophomore at Fenton High School, hurries off to his internship as soon as the final school bell of the day rings. His friends wonder where he is rushing off to.

“Are you going to McDonald’s or something?” they asked.

“No, I have to clock in at 4pm at my internship at OSG,” Garcia replied, and then ran to meet his mother in the school parking lot.

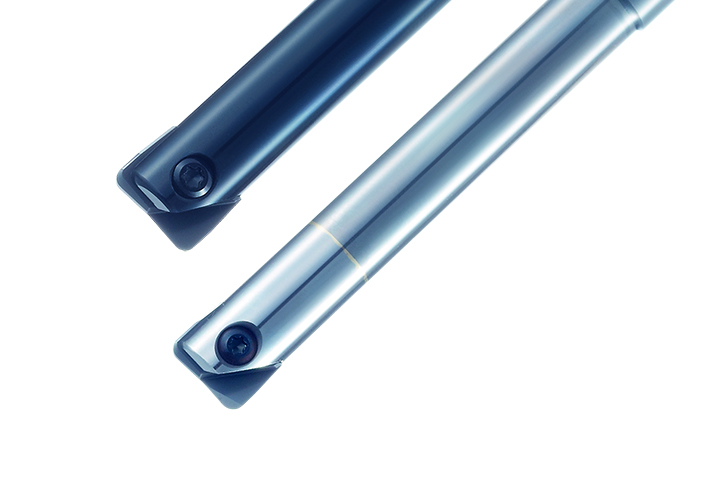

Garcia works as a Jr. Manual Operator intern at OSG. He comes in on Tuesdays and Thursdays from 4pm to 8pm. He works on the manual grinding machines to acquire hands on experience. He also job- shadows OSG CNC operators.

When he is not at OSG, he is a straight- A student and a basketball player at Fenton High School. He participates in PLTW (Project Lead The Way) program where he learns the basics of engineering principles. He is also enrolled in the accelerated classes which have more challenging content and a greater amount of homework than the traditional classes.

“It is challenging to juggle my internship, school work and sports,” said Garcia. “After I get home from OSG around 8:15pm, I sit down at the kitchen table for dinner with my mom, work on my homework and then I finally I go to bed.”

You are probably wondering what is pushing him to do all of this. Paul has a dream, a dream to be a mechanical engineer. He believes that this internship at OSG is a great opportunity to gain manufacturing experience before he pursues his career in engineering.'

In November 2015, Garcia attended the annual Manufacturing Expo hosted by College of DuPage. He met OSG’s HR Generalist, Paul Wilhelm, where he learned about the internship opportunity.

“I thought this was a big opportunity as soon as I heard about it,” said Garcia. “I had to take it before anyone else takes it. It is not every day that I come across this type of opportunity.”

Garcia and his parents are aware of the stigmas the society has toward manufacturing. Garcia himself used to think that manufacturing jobs were tiring and dirty. However, his negative perception was debunked when he learned how much technology OSG uses in the factory and how clean the factory floor is. His family also supports his decision to work in a factory setting.

“My parents are very proud of me,” said Garcia. “I went through the entire hiring process by myself from contacting Mr. Wilhelm to going on my first interview.”

Garcia’s next step is to go attend college and study engineering. He is already thinking about pursuing a Master’s degree in mechanical engineering. Watching a student like Garcia strive for his dream makes us at OSG hopeful and excited for the future of manufacturing. We are committed to helping students acquire additional experiences and skills outside of school and prepare them for their manufacturing careers.

Contact Us

Contact Us  Product Search

Product Search