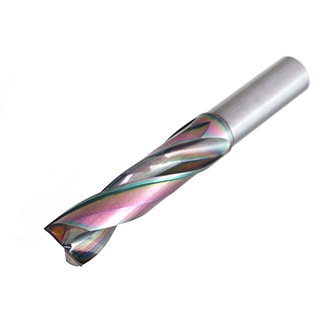

A Brand ADF (5700)

High Performance Carbide Flat Drills Designed for Various Applications

Overview

Machining a flat hole traditionally required the use of an end mill and a drill. The A Brand ADF enables one-step drilling to simplify machining time and tool management. Suitable for a wide variety of drilling applications including inclined surfaces, curved surfaces, counterboring, eccentric holes, thin plates, etc.

Features

EgiAs coating

Supresses friction with the wear resistance layer and prevents breakage

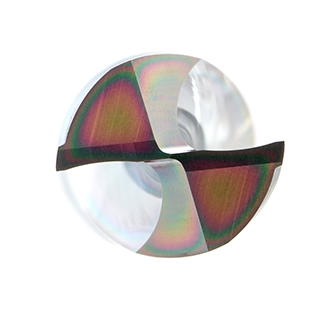

Wide chip room

Smooth chip evacuaiton

Unique end cut geometry

Reduces cutting force to enable stable machining

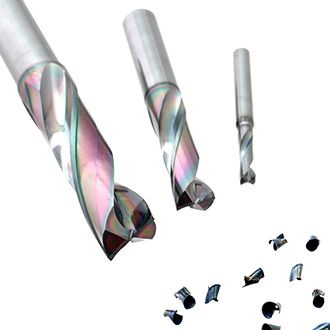

Lineup

Series

List 5700 - A Brand ADF - 2xD View Offering > View Overview >

Alternate Products

List 5700 - A Brand ADF - 2xD View Offering > View Overview >

List 5705 - A Brand ADFLS - 2xD, Long Shank View Offering > View Overview >

List 5720 - A Brand ADFO - 3xD, Coolant Through View Offering > View Overview >

Applications

Carbon Steels

Alloy Steels

Die Steels

Cast Iron

Hardened Steels < 35 HRC

series.Application6

Application Guide

| ISO | Work Material | Recommended |

|---|---|---|

| P | Low Carbon Steel : 1010, 1018 |

|

| P | Medium Carbon Steel : 1035, 1045 |

|

| P | High Carbon Steel : 1065 |

|

| P | Alloy Steels : 4140, 4340 |

|

| P | Die Steels |

|

| M | Stainless Steels : 300 |

|

| M | Stainless Steels : 400 |

|

| M | Stainless Steels : 17-4PH |

|

| K | Cast Iron |

|

| N | Aluminum : 6061, 7075 |

|

| N | Aluminum : Casting |

|

| S | Nickel Alloy : Inconel |

|

| S | Titanium : 6AL4V (30HRC) |

|

| H | Hardened Steels : ~35 HRC |

|

| H | Hardened Steels : 35-45 HRC |

|

| H | Hardened Steels : 45-50 HRC |

|

| H | Hardened Steels : 50-70 HRC |

|

good

good  best

best

Contact Us

Contact Us  Product Search

Product Search