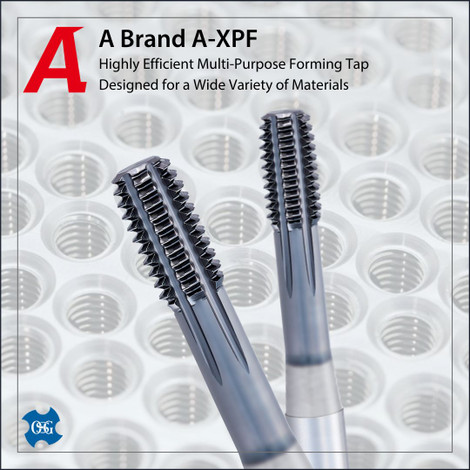

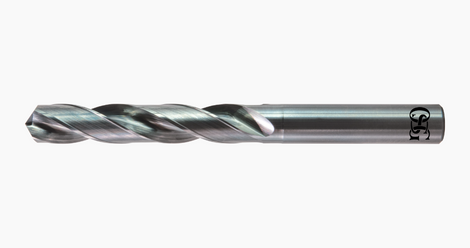

OSG USA A Brand A-XPF Forming Tap Series Expansion

19th Dec 2025

We are pleased to announce the expansion of our A Brand A-Tap series with the introduction of the A-OIL-XPF. The A Brand A-XPF is a series of advanced performance, multi-purpose forming…