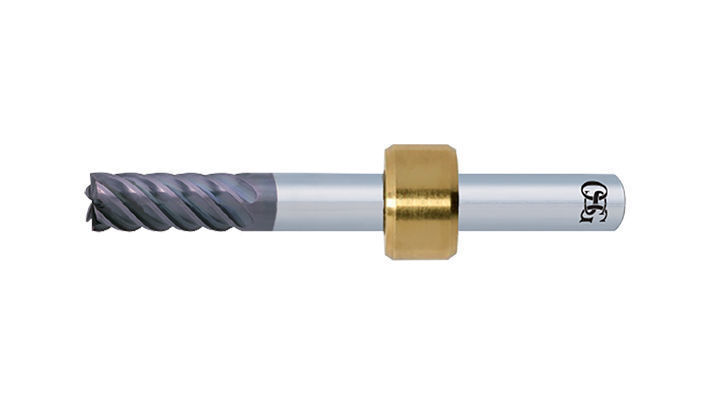

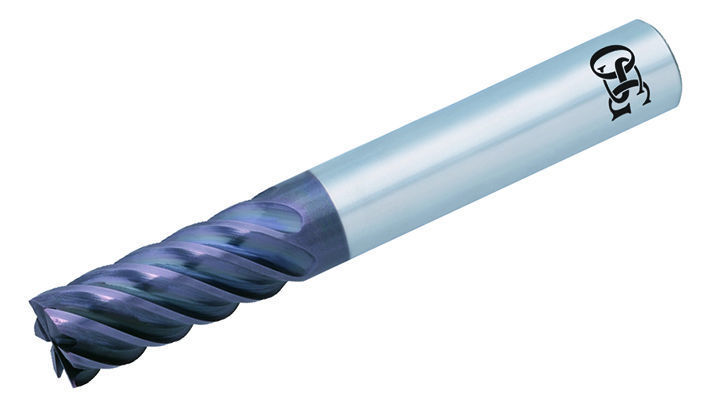

EXOCARB® Dental WXS® (4940)

Premium High Performance Dental Carbide End Mills for PEEK, Wax/PMMA, Zirconium & Titanium Materials

Overview

EXOCARB®-WXS® end mills are the new industry standard for hard milling. Everything about WXS is designed for rigidity and performance. Substrates, geometry, and our proprietary WXS coating makes this the ideal tool for use in a wide range of Dental applications.

Features

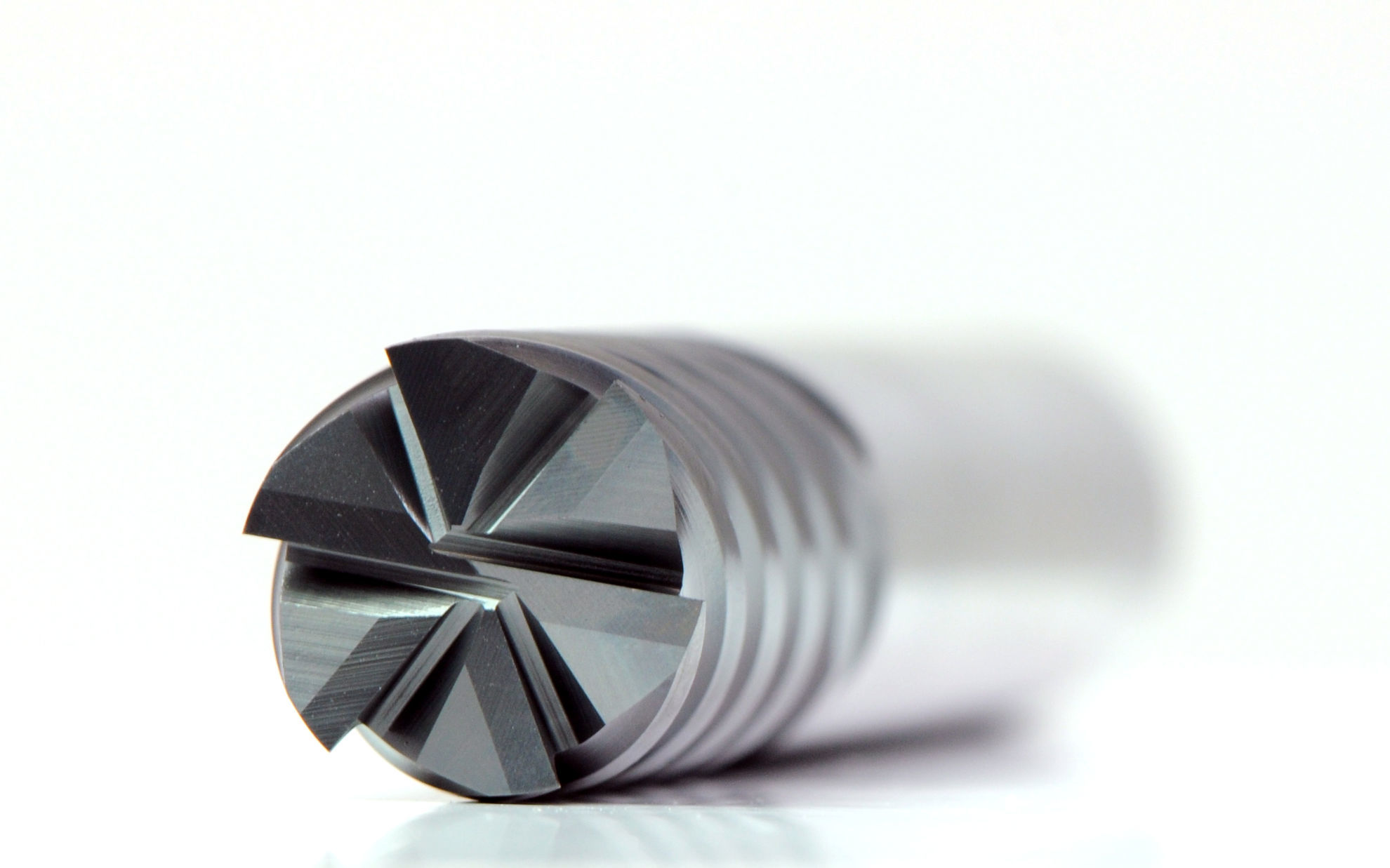

Ultra-fine micrograin carbide

The hardest most wear resistant carbide possible for incredible wear resistance

High Precision geometry - All corner radius & ball mills have +/-5um radius tolerance

High accuracy all but eliminates need for benching and rework for mold makers

High strength core diameter

Tools utilize thicker core diameters for the ultimate in strength and rigidity

WXS coating - +1300 Celsius Oxidation Temp. & +3500Hv in hardness

Higher coating oxidation temp & hardness dramatically improve wear resistance

Lineup

Series

List 4940 - Dental WXS®, 4 Flute, Regular Length, Square End View Offering > View Overview >

Applications

OSG's WXS Coating has excellent surface hardness and heat resistance, reducing material adhesion, prolonging tool life

Compatible with imes-icore Milling Systems

Designed for PEEK, Wax/PMMA , Zirconium & Titanium Materials

Application Guide

| ISO | Work Material | Recommended |

|---|---|---|

| P | Low Carbon Steel : 1010, 1018 |

|

| P | Medium Carbon Steel : 1035, 1045 |

|

| P | High Carbon Steel : 1065 |

|

| P | Alloy Steels : 4140, 4340 |

|

| P | Die Steels |

|

| M | Stainless Steels : 300 |

|

| M | Stainless Steels : 400 |

|

| M | Stainless Steels : 17-4PH |

|

| K | Cast Iron |

|

| N | Aluminum : 6061, 7075 |

|

| N | Aluminum : Casting |

|

| S | Nickel Alloy : Inconel |

|

| S | Titanium : 6AL4V (30HRC) |

|

| H | Hardened Steels : ~35 HRC |

|

| H | Hardened Steels : 35-45 HRC |

|

| H | Hardened Steels : 45-50 HRC |

|

| H | Hardened Steels : 50-70 HRC |

|

good

good  best

best

Contact Us

Contact Us  Product Search

Product Search