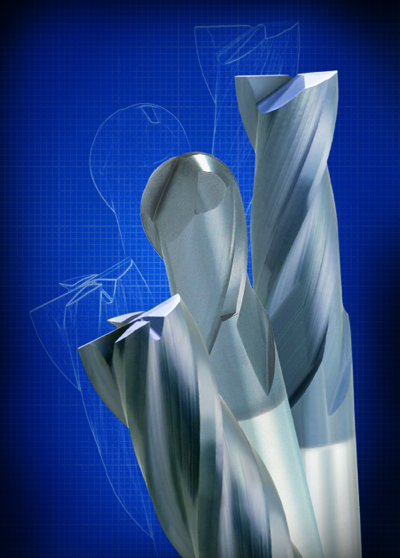

For milling pre-hardened and hardened steels, you need an end mill that won’t wear down. OSG’s premium high performance carbide end mills, the EXOCARB® WXL® and the EXOCARB® WXS®, are specially designed for rigidity and performance in even the toughest materials and milling applications.

The WXL® is specifically tailored for nonferrous materials and mild steels up to 55HRC, and can withstand up to 1100 degrees Celsius. The WXS®, on the other hand, is made for hardened steels like D2, A2, S7, H13 and CPM, milling up to 65HRC and able to withstand up to 1300 degrees Celsius.

For added strength, our WXS® and WXL® have thicker core diameters and are made of the hardest carbide possible for incredible wear resistance. The higher coating oxidation temperature and hardness keep these end mills performing long after the competition wears out.

Ideal for the Mold & Die industry, the WXS® and WXL® utilize high precision geometry with a +/- 5um radius tolerances for both corner radius and ball end mills, eliminating the need for benching and reworking.

With hard carbide materials combined with high precision, the EXOCARB® WXS® and WXL® are the top hard milling solutions.

Contact Us

Contact Us  Product Search

Product Search