David

Aly, Aerospace Specialist

Just

because you’ve tried one forming tap, doesn’t mean you’ve tried them all. We

had the recent opportunity to prove that OSG forming taps are better than the

rest.

As

a supplier of custom fabricated metal products and machinery, one of our customers

approached us wanting to get better chip control during their tapping operation.

Located in Winona, Mississippi, they have a 92,500 square foot manufacturing

facility for producing fuel tanks, hydraulic tanks and custom designed

machining fixtures.

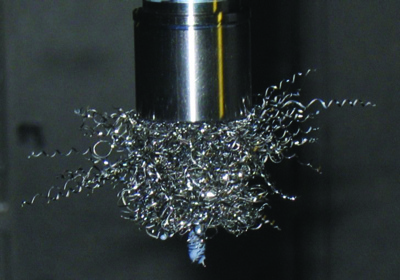

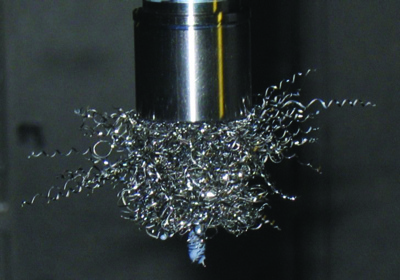

After

discussing the customer’s chip control needs, I recommended OSG’s EXOTAP® NRT® Forming Tap, a more stable, thread rolling tap that

makes threads by compressing the work material without creating chips. Because no chip is

produced, breakage due to chip packing and bird nesting is eliminated.

The

EXOTAP® NRT® also has significantly reduced friction

resistance because of its special threading design and surface treatment. Made

from VC-10 Powdered Metal High Speed Steel, this forming tap has a longer tool

life when tapping difficult to machine materials like carbon steels, alloy

steels, stainless steels and aluminum alloy.

Initially,

the shop foreman, Mr. William Smith, was hesitant about using a forming tap due

to a bad experience with a competitor’s brand. After I showed William a

presentation and a chip flow demonstration video, he was willing to give our

forming tap a chance.

We

approached his staff with OSG’s EXOTAP® NRT® Forming Tap in hand. After explaining the test with the operator

and reiterating?that there will be no chips, we began the trial.

A

few days later, I called to check in on their progress. William

enthusiastically explained that he was still running the same tap. He had lost

count of the number of holes produced but assured me that it was well over 1,000

holes! After such a successful run with the first test tap, he purchased more

of the test size, now truly convinced that all forming taps are not created equal.

Contact Us

Contact Us  Product Search

Product Search