Ultra-machining efficiency and stability in steel applications

- Takahiro Yamamoto, OSG Corporation Applications Engineer (Drill Development Division)

Three-flute drills are commonly employed in manufacturing. However, they are mostly used in the processing of materials with short cutting chips and low cutting resistance, such as cast iron, ductile cast iron and aluminum alloy. Three-flute drills are sometimes advertised to be suitable for steel materials such as carbon steel, alloy steel and mild steel. However, with a smaller chip room geometry than 2-flute drills, the cutting thrust resistance in 3-flute drills is also greater.

Due to constraints in workpiece configuration, equipment and setup, conventional 3-flute drills often are unable to maximize both speed and precision as advertised. Moreover, in steel processing, the strength of the work material and viscosity are high, making chip separation and stable processing a challenge. With high thrust force and poor chip evacuation, sudden machining troubles such as tool breakage and chipping are common headaches of 3-flute drills.

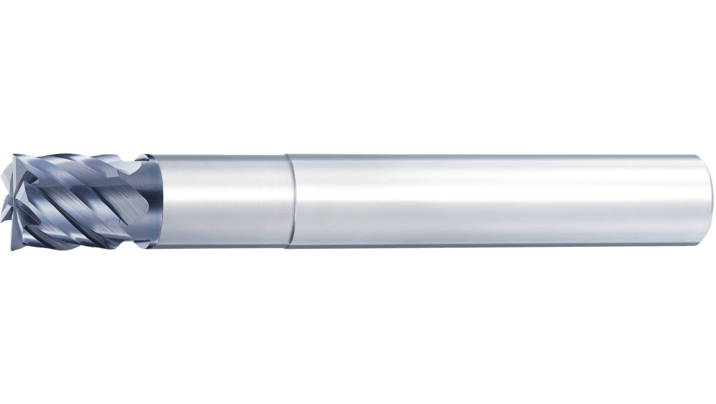

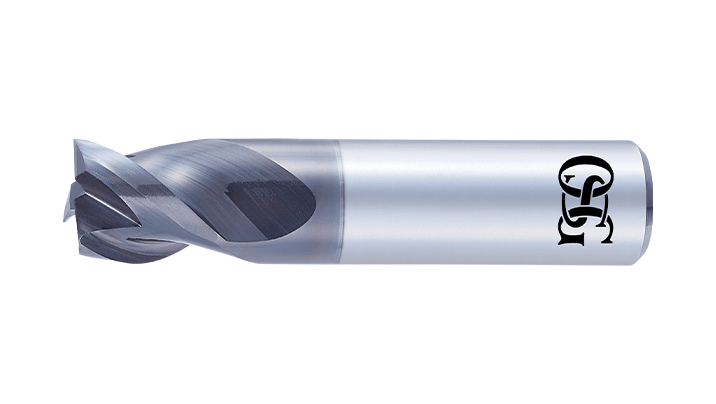

To help manufacturers maximize productivity, OSG has recently introduced a new revolutionary drilling innovation – the ADO-TRS – nicknamed as the ‘Triple Revolution’ drill, for ultra-machining efficiency and stability in steel materials.

Features of ADO-TRS ‘Triple Revolution’ Drill

There are three major features that enable the ADO-TRS to stably process steel applications.

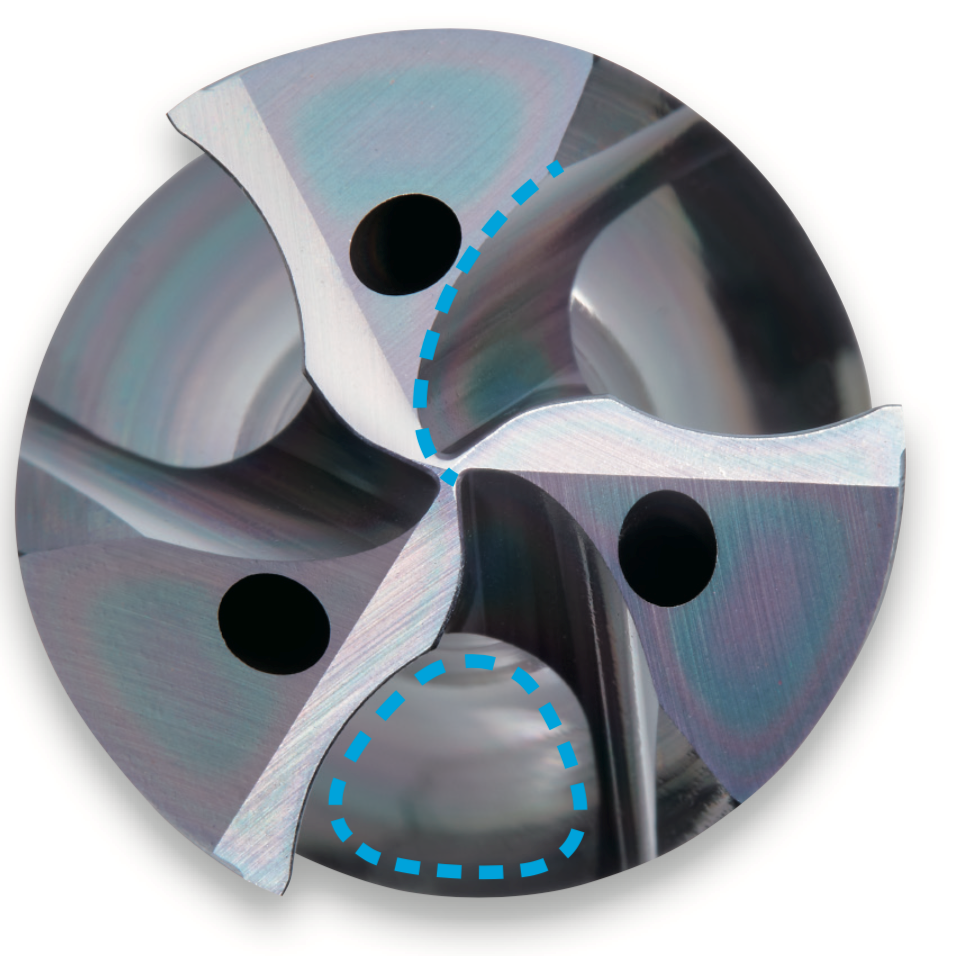

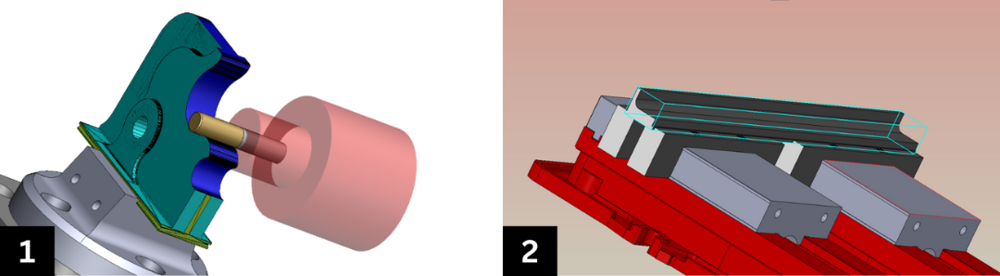

The most notable key feature is the newly engineered R gash geometry (pat. P) as illustrated in figure 1.

Figure 1. ADO-TRS’ unique R gash geometry enables low cutting resistance and creates short and compact chips stably.

The optimized R shape geometry is designed to control chip flow direction to facilitate trouble-tree chip-evacuation. With this new feature, the ADO-TRS is able to significantly improve chip separation even in steel materials by breaking them into small pieces and consistent shape. In addition, this new geometry can reduce cutting resistance (thrust resistance), by as much as 30 percent versus conventional tooling, enabling it to outperform even 2-flute drills in high-feed processing with minimal cutting resistance.

The second key feature of the ADO-TRS is its wide chip pocket configuration.

In 3-flute drills, chips are difficult to be discharged from the center of the drill. The ADO-TRS employs a wide chip room flute geometry to improve chip ejection. Combined with the R gash specification, chips are curled for greater separation capability, which leads to smooth and stable chip evacuation.

Last but not least, the ADO-TRS is coated with OSG’s original EgiAs coating for high durability. The EgiAs coating is consist of overlapping nano-periodical layers and wear-resistance layers, engineered to suppress the propagation of cracks that are likely to occur during drilling. The wear-resistance layer is composed of multiple hard layers; while the nano-periodical is a combination of hard and soft layers. With a mixture of hard and soft layers, internal stress can be relieved, allowing the EgiAs coating to achieve both high wear resistance and extreme toughness to ensure stable and consistent tool life under aggressive cutting conditions.

Cutting Data

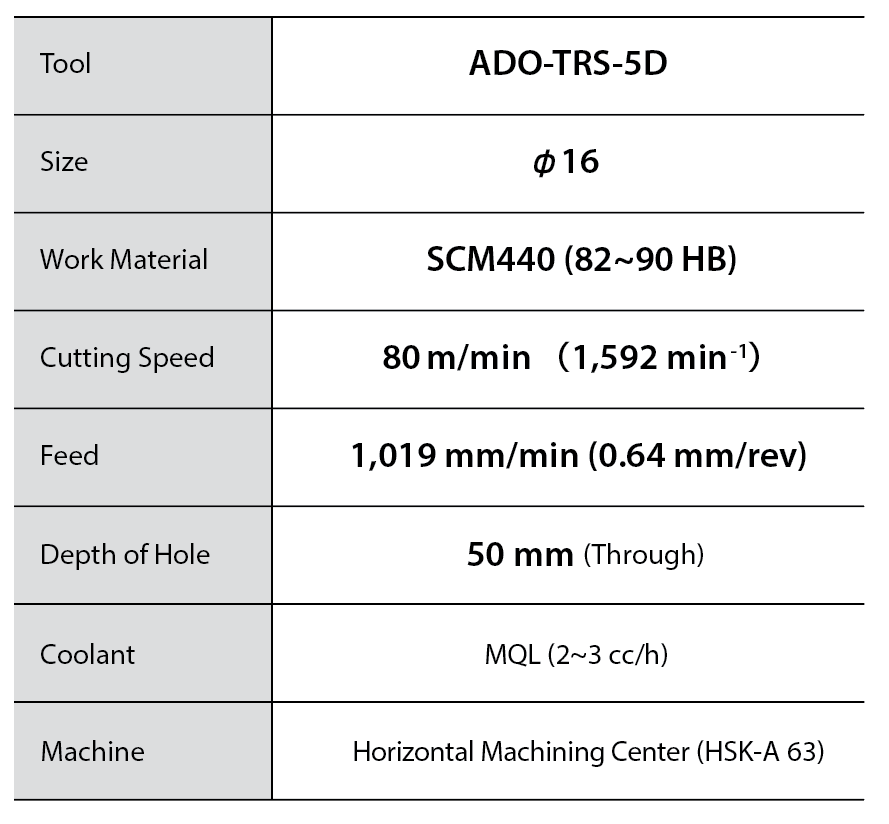

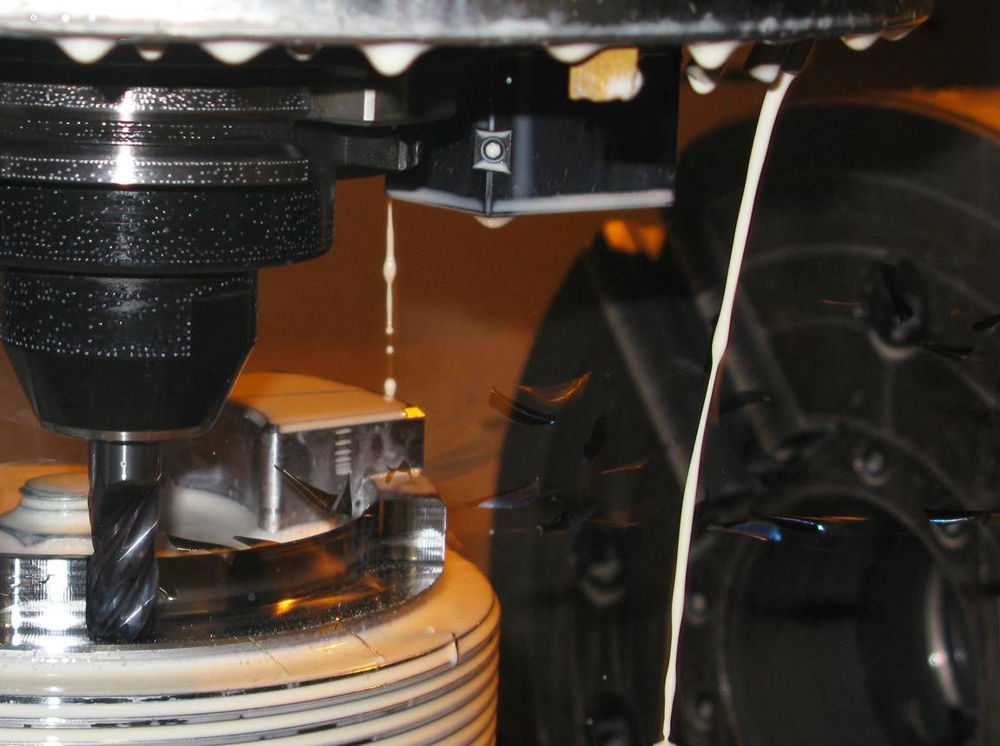

1. Excellent Chip Formation and Evacuation in Steel Applications

Two of ADO-TRS’ most notable benefits are its superior chip management and low resistance drilling capability in steel materials.

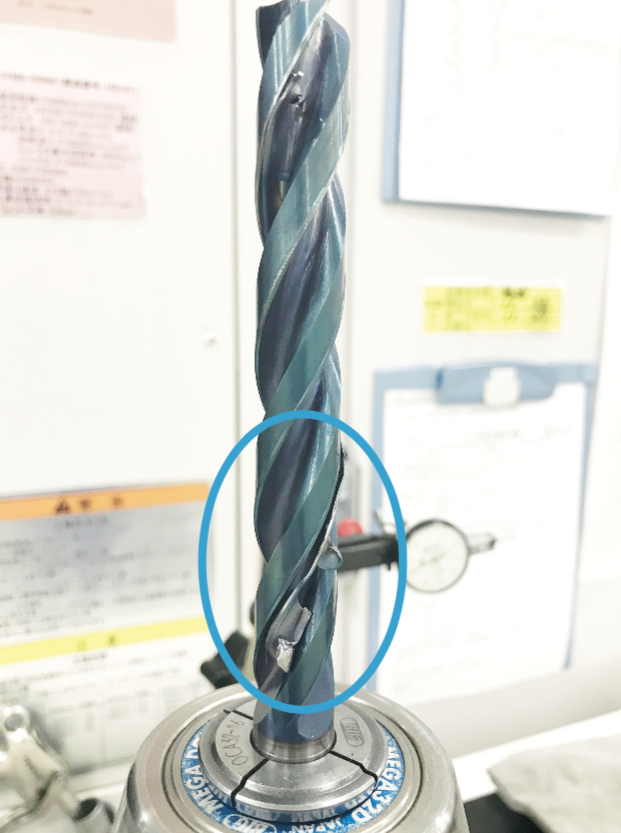

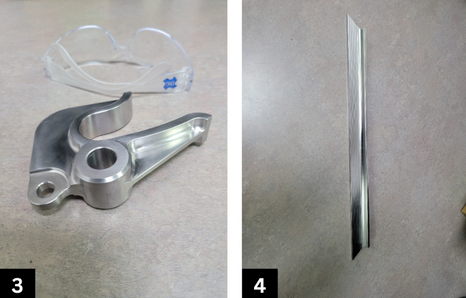

SCM440 (raw) is one of the more viscous materials among steels. When processing this material with MQL, chips generated by conventional 3-flute drills and 2-flute drills are elongated as depicted in figure 2. As depicted in figure 3, the conventional 3-flute drill is unable to break chips into small pieces. As a result, remnants of elongated chips remain in the flute of the drill. The ADO-TRS, on the other hand, is able to demonstrate excellent chip form consistently as shown in figure 2.

Figure 2. Chip shape comparison in SCM440.

Figure 3. Condition of the conventional 3-flute drill after processing SCM440.

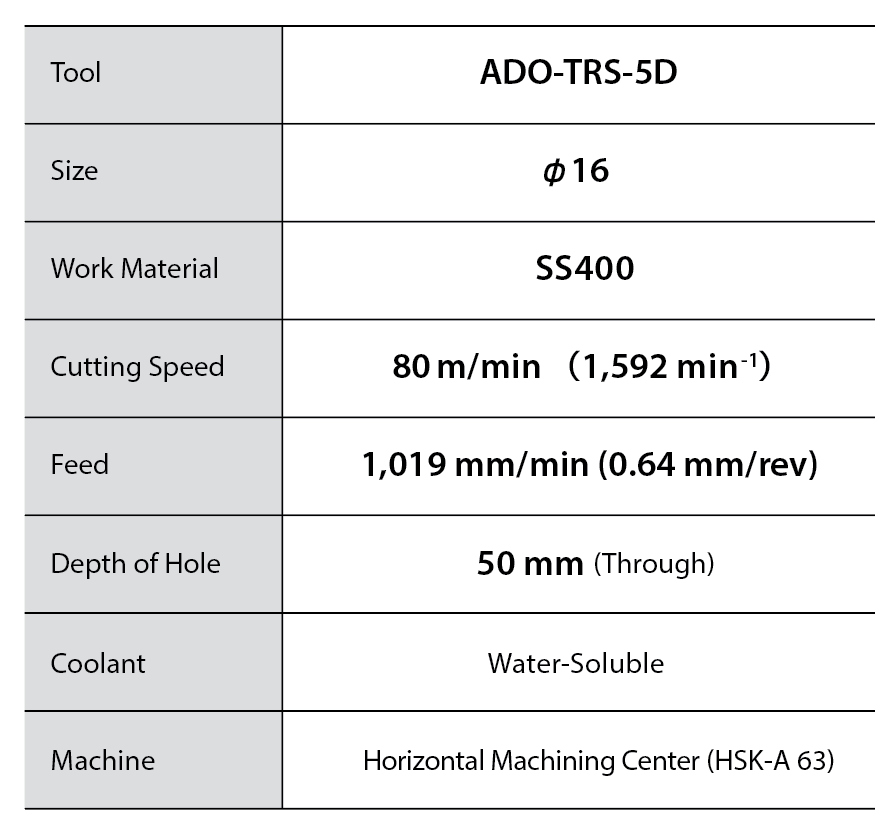

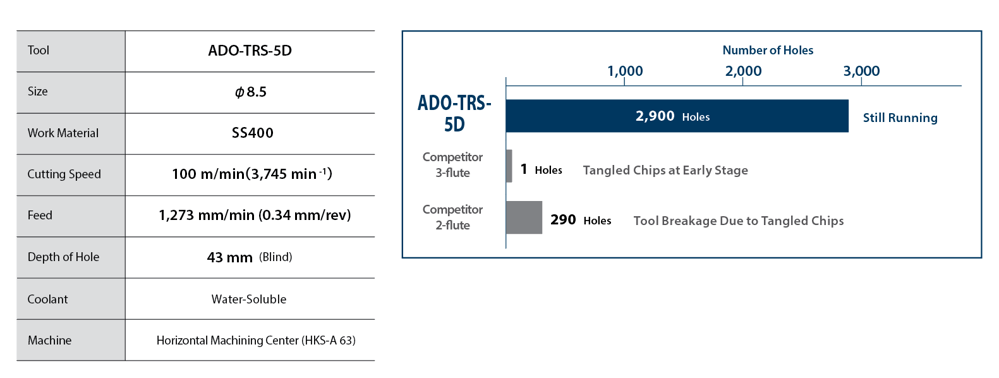

Figure 4. Chip shape comparison in SS400

Figure 5. Tool life comparison in SS400

Moreover, in the processing of SS400 using water-soluble coolant, sudden tool damage and chipping caused by tangled chips are prone to occur. The stability in chip formation and evacuation is a key factor for achieving stable processing in mild steel SS400, which is particularly prone to chip problems. As illustrated in figure 4 and figure 5, the ADO-TRS demonstrates overwhelming chip separation capability and long tool life even in the processing of SS400 in comparison to the conventional 3-flute drill and 2-flute drill.

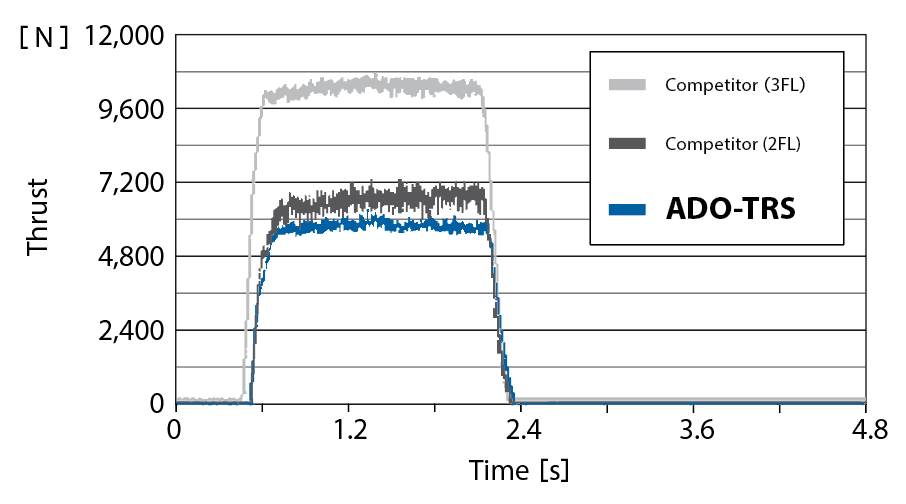

2. Low Resistance Drilling

Next, figure 6 illustrates a comparison of cutting resistance when processing under the cutting condition depicted in figure 2.

Figure 6. Cutting resistance (thrust resistance) comparison in SCM440.

As shown in figure 6, the ADO-TRS is able to reduce thrust resistance by approximately 35 percent versus conventional 3-flute drills, and generated even less overall thrust resistance when compared to a standard 2-flute carbide drill, which has one less flute and larger chip rooms. Under identical cutting condition, the ADO-TRS is able to achieve the lowest thrust resistance.

Due to high cutting resistance inherent in conventional 3-flute drills and the various constraints present in processing environment, such as the machine, workpiece geometry, work fixture, etc., conventional 3-flute drills are often unable to maximize high-feed performance and precision. The ADO-TRS, on the other hand, excels in wide range of cutting conditions, truly reflecting its versatile capability.

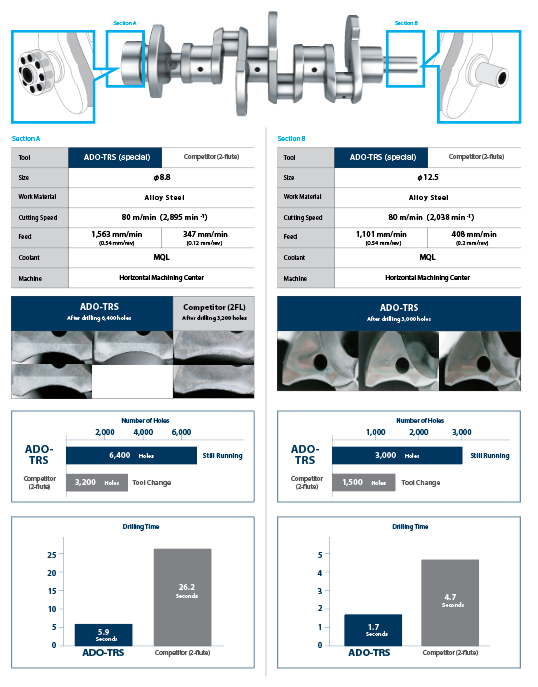

Next, we will evaluate the performance of the above features combined with OSG’s original EgiAs coating in the following case study, where the ADO-TRS is able to demonstrate long tool life and stable processing in a crankshaft made of alloy steel. In terms of shape, although the work holding force (clamp) at the time of processing is not high, the effect of the low cutting resistance of the ADO-TRS is able to surpass the carbide 2-flute drill with greater feed-rate. As shown in figure 7, the ADO-TRS is able to achieve higher efficiency and significantly reduce processing time versus the competitor 2-flute drill.

Figure 7. Case study of machining time and tool life improvement in the processing of an automotive crankshaft.

As depicted in this case study, the ADO-TRS is able to demonstrate exceptional stability, high-productivity, long tool life in steel materials, which conventional tools are challenged by instability. Furthermore, with capabilities to resolve common challenges of 3-flute drills such as high thrust force and poor chip evacuation in steel applications, the ADO-TRS is setting a new standard for 3-flute drills with reliable performance never witnessed before in the cutting tool sector.

The ADO-TRS’ unique R gash geometry feature has also been applied to OSG’s ADO 40xD and 50xD carbide drills with through coolant for highly efficient deep-hole drilling. The R gash geometry enables super low cutting resistance and exceptional chip control, optimized for superior performance in ultra-deep-hole applications. This geometry has proven success not only in 3-flute drills, but also in 2-flute drills. OSG will look to apply its superior tooling geometry to other products to further enhance productivity, tool life, stability and precision.

For manufacturers who are especially struggling with chip evacuation problems in steel applications, look to the ADO-TRS to experience ultra-machining efficiency and stability.

The ADO-TRS is available from diameter 3 mm up to 20 mm, in processing depth of 3xD and 5xD, and is suitable for applications in carbon steels, alloy steels, mild steels, cast iron and hardened steels.

Photo Captions

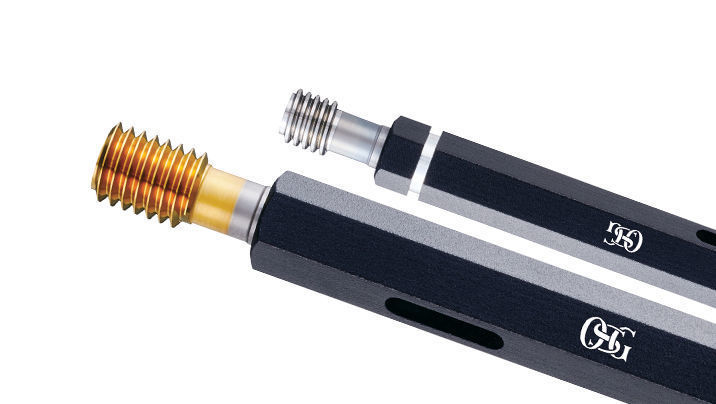

ADO-TRS.The ADO-TRS ‘Triple Revolution’ is OSG’s latest drilling innovation for ultra-machining efficiency in a wide range of materials. Its unique R gash geometry enables high thrust resistance and exceptional chip control, which are common challenges of 3-flute drills.

ADO-40xD 50xD. The ADO-TRS’ unique R gash geometry feature has also been applied to OSG’s ADO 40xD and 50xD carbide drills with through coolant for highly efficient deep-hole drilling. The R gash geometry enables super low cutting resistance and exceptional chip control, optimized for superior performance in ultra-deep-hole applications.

_1000.png)

_1000.png)

_1000.png)

Contact Us

Contact Us  Product Search

Product Search