A Brand AE-CR-VTS-N (8870)

Advanced Performance DLC Coated End Mills for Non-Ferrous Materials

Overview

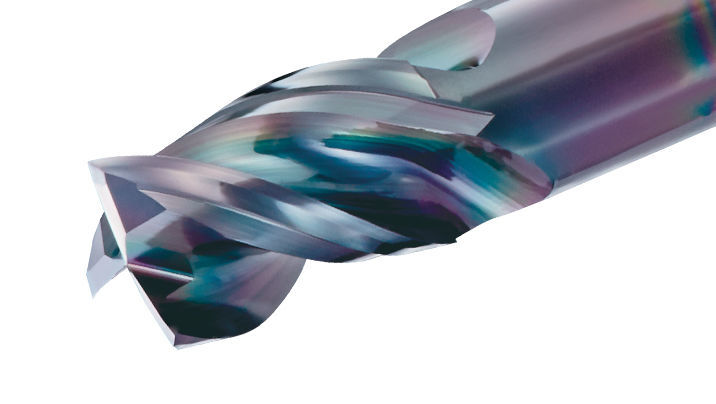

The AE-CR-VTS-N high performance DLC coated carbide end mill for non-ferrous materials is suitable for a wide variety of applications with high efficiency and quality. Its DLC-IGUSS coating further improves tool life with excellent welding resistance and lubricity, which is effective in the machining of non-ferrous materials such as aluminum alloys.

Features

Flat cutting edge

Achieves higher precision machined surface quality

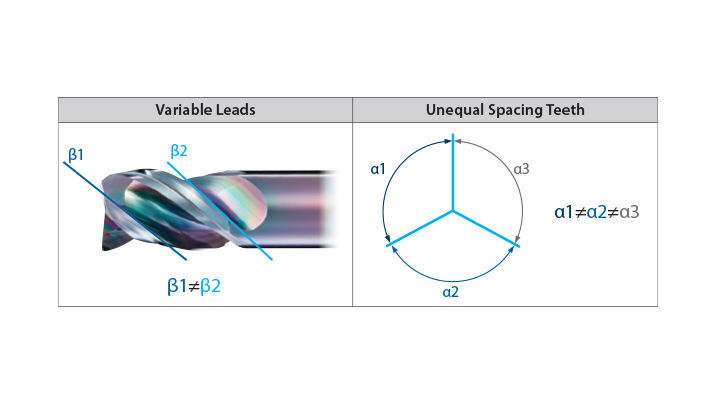

Large core design

High rigidity prevents chattering

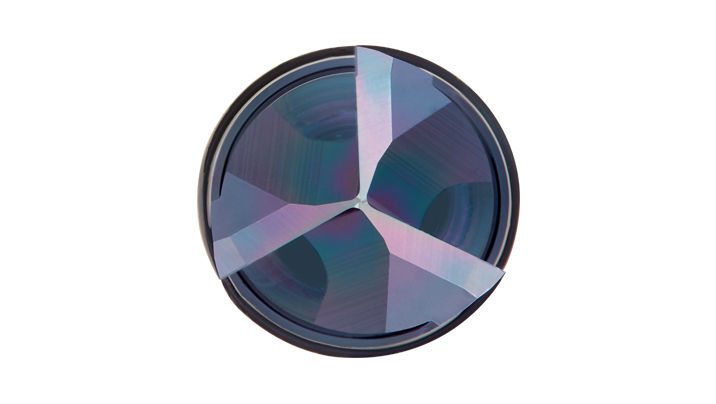

Center cutting edge

Can be used for plunging

3 cutting edges at center

For high speed milling

Vibration suppression

Stable and high efficiency milling

Lineup

Series

List 8870 - A Brand AE-VTS-N - Inch View Offering > View Overview >

Application Guide

| ISO | Work Material | Recommended |

|---|---|---|

| P | Low Carbon Steel : 1010, 1018 |

|

| P | Medium Carbon Steel : 1035, 1045 |

|

| P | High Carbon Steel : 1065 |

|

| P | Alloy Steels : 4140, 4340 |

|

| P | Die Steels |

|

| M | Stainless Steels : 300 |

|

| M | Stainless Steels : 400 |

|

| M | Stainless Steels : 17-4PH |

|

| K | Cast Iron |

|

| N | Aluminum : 6061, 7075 |

|

| N | Aluminum : Casting |

|

| S | Nickel Alloy : Inconel |

|

| S | Titanium : 6AL4V (30HRC) |

|

| H | Hardened Steels : ~35 HRC |

|

| H | Hardened Steels : 35-45 HRC |

|

| H | Hardened Steels : 45-50 HRC |

|

| H | Hardened Steels : 50-70 HRC |

|

good

good  best

best

Contact Us

Contact Us  Product Search

Product Search